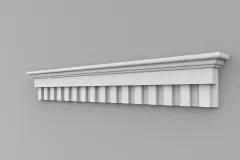

Verolith. Façade profiles and 3D elements

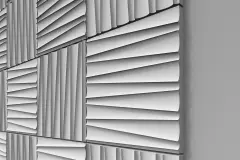

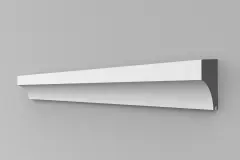

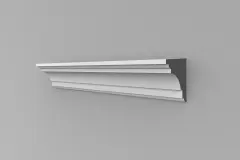

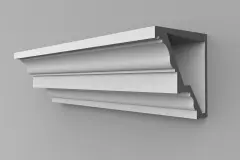

Texture and Shape: Bespoke surfaces, textures & profiles. Using CAD/CAM techniques verolith is cut using a CNC Router—a computer controlled cutting machine—to shape it into any design of form or pattern.

Colour and Finish: The board joints and fixing points are filled, sanded and finished with a compatible coating from the extensive Sto range of smooth, textured, matt or gloss coatings.

Technical Considerations: The thickness of the material ranges from 40mm to 200mm or in the case of large profiles, as a hollow section.

References

StoVerolith has been successfully used on a huge range of projects in all climatic conditions. Click here to see just a few examples of where the material has been used to restore an existing classical façade, or CNC cut to provide innovative and interesting façade embellishment.

Case study

Meet the Architect: Sam Jacob Studio on ‘One Thing After Another’ and Sto Verolith

Studio director Sam Jacob and architect Eddie Blake describe the design processes behind ‘One Thing After Another’, an installation at Sto Werkstatt that explored the use of Sto Verolith within a digital design process.

“What really fascinated us was the possibility to try and essentially take a piece of architecture through a digital process and output it again.” -Sam Jacob, Director at Sam Jacob Studio.

The installation investigates the possibilities of digital production that go beyond the blandly futuristic and suggests how new technologies can open up a wide array of design possibilities that embrace process, imperfection, narrative and history.

How can I help?

We need your consent to load the contact form!

We use a third-party service to embed contact forms and make it available to you. By clicking “Accept”, you consent to your data being processed by Salesforce Marketing Cloud Account Engagement in accordance with our CMP. You can find out more about the service by clicking “More information”. You can withdraw consent with effect for the future at any time.

Your Sto specification support team in Central London

-

Grant Littlejohn Major & International projects

Grant Littlejohn Major & International projects -

Nam Lall Midlands

Nam Lall Midlands -

James Gosling London (EC, E, N) & Acoustics

James Gosling London (EC, E, N) & Acoustics -

Phil Gilmore London (WC, W, SE, SW)

Phil Gilmore London (WC, W, SE, SW) -

Darren Greenwell Glass Rainscreen Systems

Darren Greenwell Glass Rainscreen Systems -

Amy Croft Curator of Sto Werkstatt

Amy Croft Curator of Sto Werkstatt